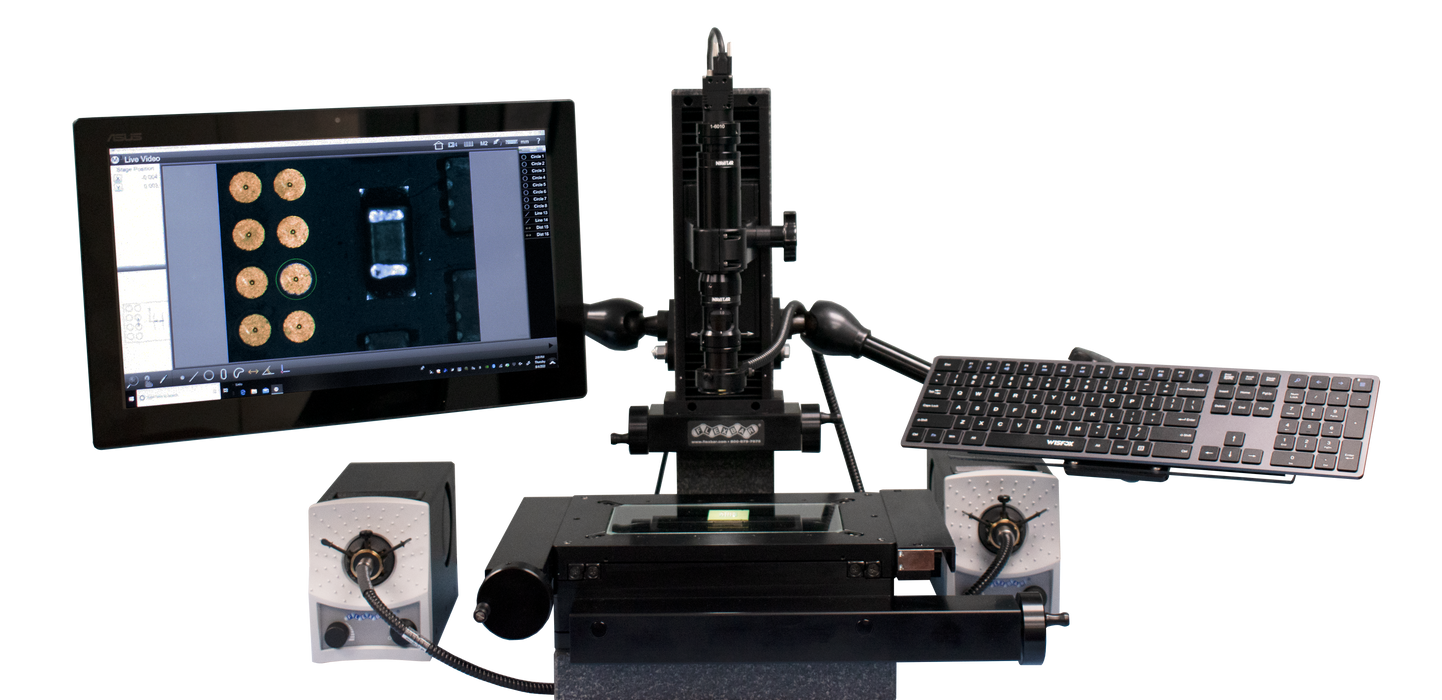

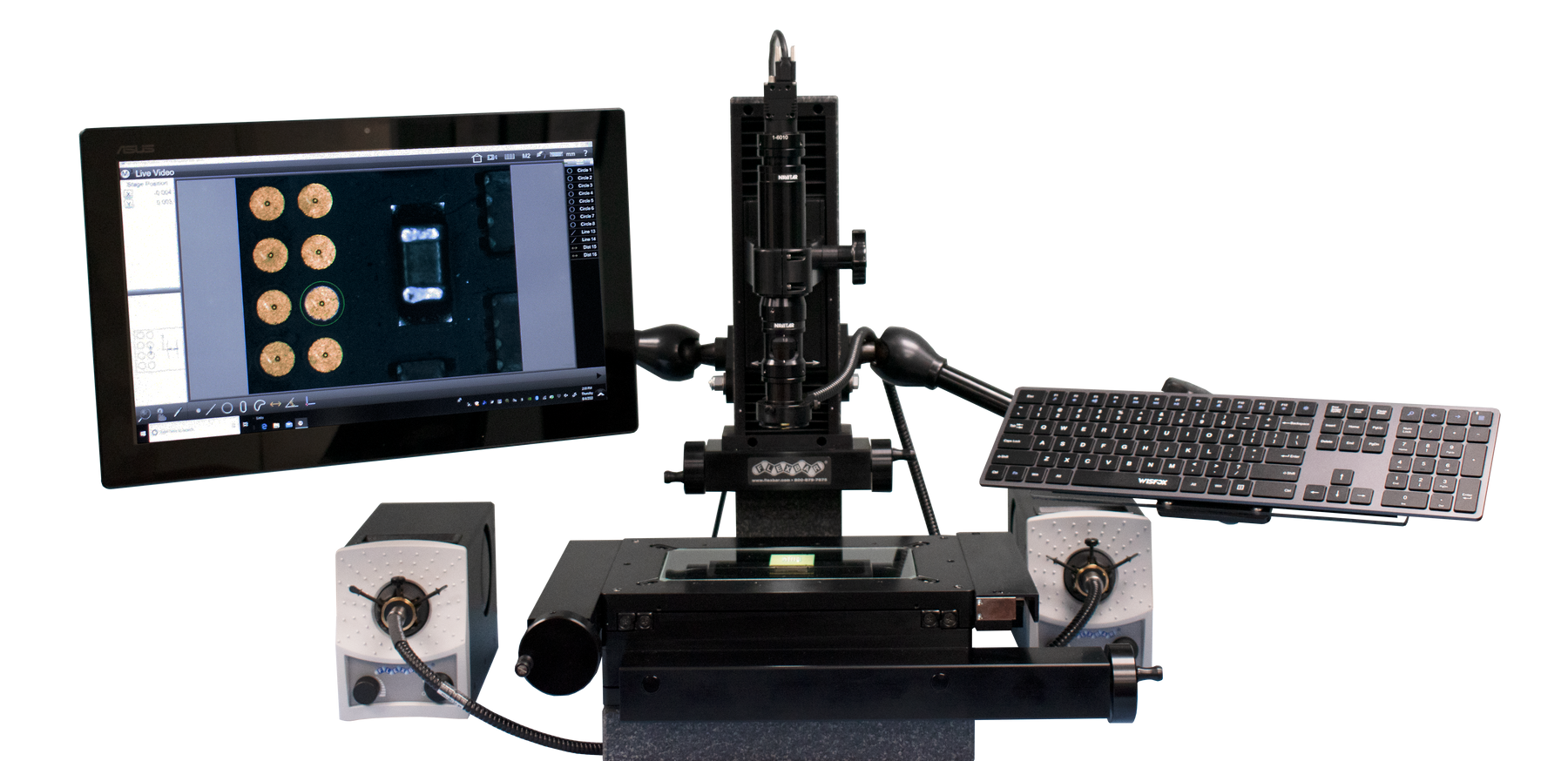

The Optiflex MLX-3000 is a Computer based optical inspection and measurement system Manufactured by Flexbar in the USA, this system is available in multiple stage sizes including 8”x4”, and 12”x12”.

A granite base and vertical Z-column makes this system sturdy and robust, able to withstand the rigors of either the shop floor or inspection lab. Whether in use for precise real time measurements, or as a featured tool in any inspection department, the Optiflex MLX-3000 system offers measurement resolution down to 0.5 microns with accuracies better than 0.0002”/0.002mm.